Bioprinting the human heart was viewed as science fiction until recently. There have been many advancements in the field of tissue and organ fabrication, which provide a clear pathway for the bioprinting of human hearts, a field that has been transformed from science fiction to reality. 3D printing technologies are emerging as a treatment of cardiac failure. Researchers have made a scientific leap toward making 3D-printed flesh and blood a reality. Today, if we need a heart transplant, we need to wait for an available and suitable organ from someone else’s body. However, there may come a day in the future when doctors go for 3D-print a replacement heart, creating a customized alternative made of bio-inks using human fatty tissue.

How Does 3D Printing of the Heart Work?

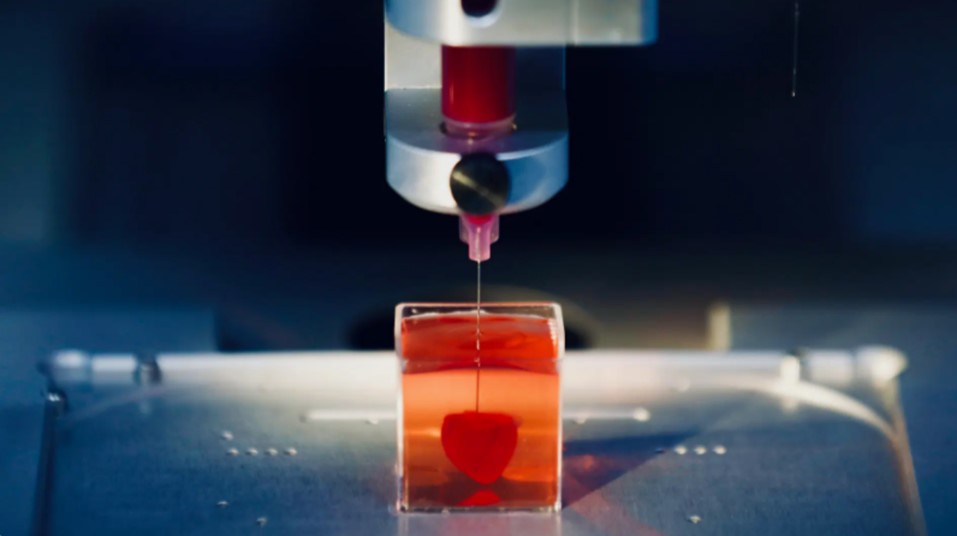

Scientists in Israel created a 3D-printed heart with human tissues and vessels. This is a major medical breakthrough that advances possibilities for transplants. Fatty tissues are reprogrammed as stem cells and a bio-ink gel is derived from these tissues. They 3D-printed a tiny, thumb-size heart in three hours. This is the first successful engineered and printed heart with cells, blood vessels, ventricles and chambers. The researchers have separated the human fatty tissue’s cellular and non-cellular components, creating stem cells which are then reprogrammed into either cardiac or endothelial cells. The non-cellular components and programmed cells together formed a “hydrogel” or “bio-ink,” used in the printing process. After being mixed with the hydrogel, the cells were differentiated to cardiac or endothelial cells to create patient-specific cardiac patches with blood vessels to produce an entire heart. According to the researchers, the model heart can be a useful tool to guide medical professionals in operations related to human heart function. It provides a basis for new research on using 3D printing technology to produce fully operating hearts to replace in people. In our process, bioinks, substances made of sugars and proteins can be used for 3D printing of complex tissue models. At this stage, the 3D-heart is small, the size of a rabbit’s heart. Larger human hearts also require the same technology.

SWIFT (sacrificial writing into functional tissue) is a biomanufacturing process that involves collecting human cells from patients and transforming them via stem cells into cardiac cells. These cells are packed together and 3D-printed vascular structures are then printed in gelatin ink into them to create a channel network that mimics the structure of real-life human vascular networks. In a recent study, a team 3D printed a small heart using human tissue, including working blood vessels. The 3D-printed miniature heart does not pump or function yet but does contract like a heart does. It is tiny, but it is key progress towards a full-size, transplantable 3D printed heart. The findings demonstrate the potential of engineering personalised tissue and organ replacement in the future. Still, scientists are a long way off from actually making this 3D-printed heart function like a real human heart and transplanting it in a living creature. This process involves the use of cells and growth factors to create tissue-like structures and eventually organs.

3D-printed hearts offer an exciting alternative option to current systems of organ donation. 3D printing holds the promise of improving the healthcare industry by presenting products such as smarter drugs and hyper-customized prosthetics. 3D printing is a growing technology and is a subject to monumental discoveries.