The Efficacy of a Novel Temporary Crown System Marginal Seal and Structural Durability in Terms of Cyclic Loading - A Pilot Study

A B S T R A C T

Background and objectives: There has been a lack of studies regarding the marginal seal and structural durability of a novel temporary crown system (Hi-tempo) manufactured from a polylactic (PLA) based resin thermoplastic material especially in terms of cyclic loading. Therefore, the purpose of this pilot study was to investigate the efficiency of this novel temporary crown system’s (Hi-tempo) marginal seal and structural durability in terms of cyclic loading.

Methods: A crown preparation was duplicated in bovine teeth (n =15) using a copy mill machine. The specimens were divided into three groups and temporary crowns were fabricated that consisted of: control group, Luxatemp (bis-acrylic), Hi-tempo crown, PLA based and Hi-tempo window type crown, PLA based with resin cusps. Marginal dimensional change was measured before and after cyclic loading with a 93.36 N force, 0.63 HZ, for 45360 cycles (stimulating 21 days in vivo) in water pigmented with a red dye. The marginal change was statistically analysed and the surface roughness was analysed using scanning electron microscopy (SEM).

Results: Statistical significance (p<0.05) was found in the marginal changes of the control versus the Hi-tempo window and the Hi-tempo groups. SEM analysis revealed that the control crowns, had a much rougher surface with micro-cracks compared to PLA based crowns which had homogenous surfaces. All the specimens showed leakage of the red dye into the internal fitting surfaces of the crowns.

Conclusions: The novel system showed promising and comparable results in terms of structural durability and marginal seal compared to the conventional system.

Introduction

Provisional restorations play an important role in fixed prosthodontic treatment. Their goal is to stabilize the prepared tooth, protect it from the harsh oral environment and provide natural aesthetics [1]. Overall a provisional restoration performs very similar functions as a permanent crown however, with the main difference being the material the restoration is fabricated from [2]. Because temporary crowns are usually placed in the mouth for just a few weeks, the material does not need to withstand masticatory forces for long periods of time like a permanent crown. However, it still needs to meet the requirements which reflect the demands of a temporary crown [3].

There are currently a wide variety of provisional materials and associated techniques that are used in the dental field for fixed restorations [4]. The most common materials used for provisional restorations are acrylic resins [5]. These materials need to produce an appropriate marginal adaptation, not irritate the dental pulp and gingival tissues, should have low thermal conductivity, should be easy to handle and have adequate strength [6].

The choice of material is influenced by the technique that is used to make the temporary restoration. Such techniques are direct, indirect or in some cases a combination of indirect and direct [7]. The indirect technique involves the fabrication of the provisional restoration outside of the mouth, usually on a cast produced from an impression of prepared teeth while direct technique involves making temporary crown directly on the tooth [8, 9]. The most commonly used technique for manufacturing a temporary crown is the direct technique due to its shorter chair time and smaller treatment costs for the patient [10].

Whichever conventional techniques that is used to produce a temporary crown, there is still a relatively long chair time which is costly [9]. Therefore, there is a demand for a new system that will provide a faster and a more cost-effective way of manufacturing temporary crowns. One such solution that has been a recent introduction into the dental field is preformed crowns, in particular, temporary crowns made from polylactic acid (PLA) based thermoplastic resin material (Hi-tempo). The thermoplastic crown system consists of malleable plastic and it works by being softened in hot water (above 70 Degrees Celsius) and adapted straight onto the prepared tooth. The use of such PLA based thermoplastic material is a new development when it comes to dental prosthesis. Because PLA is a polymer which is made from renewable resources such as starch and sugar, some of the promising aspects of it is that it is sustainable, biodegradable, and biocompatible [11]. This means it has potential to save multiple resources and make treatment time faster while being sustainable, which in the modern day is an important factor for any industry [12]. However, the thermoplastic temporary crown system still requires further assessment of the marginal integrity and structural durability due to it being a relatively new system. Therefore, the purpose of this pilot study is to evaluate the marginal seal and structural durability of this novel material in terms of cyclic loading.

Materials and Method

I Master Die Preparation

15 crown preparations were prepared in a two-part process. In the first phase, 15 bovine incisors were selected to simulate human teeth. They were cleaned from debris tissue; the pulp was removed from the pump chamber and the top third of incisal edge was removed with a diamond burr. A brass pin was inserted into the pulp cavity, it was filled with Filtek™ Supreme XTE composite (3M™ ESPE™, USA) to stimulate dentine and left for 12 hours to fully set. The tooth was then mounted in SR Ivolen (Ivoclar Vivadent, Liechtenstein) to secure the specimen for copy milling into the shape of a typical full coverage crown preparation.

In the second phase, a standard posterior crown preparation of maxillary first premolar (Ivoclar Vivadent IPS e.max training kit, Liechtenstein) was scanned using Ceramill map400 scanner (Amann Girrbach, Austria). The scanned die was shrunk 20% in the Cura 3D Printing Slicing Software (Ultimaker) and the STL file was sent to a 3D printer (Ultimaker 3 Extended, USA) and printed using PLA material. The 20% shrinkage compensated for the copy mill machine (Amann Girrbach ceramillbase, Austria) milling 20% larger which cannot be adjusted. Each bovine specimen was individually milled from the same master die. The bovine crown preparations were stored in artificial saliva (Biotene Saliva substitute, USA) until needed.

II Specimen Preparation

The 15 bovine crown preparations were randomly divided into three sample groups of five specimens each. Temporary crowns for each group were manufactured and bonded to the preparations using the materials listed in (Table 1). To prepare the specimens for group A, a matrix of a standard posterior crown of the first premolar (Ivoclar Vivadent IPS e.max training kit, Liechtenstein) was made from silicone putty (Exaflex Putty, GC, Japan). The matrix was placed on top of the preparation and filled with temporary crown self-curing resin (Luxatemp Fluorescence DMG, USA), similar to the conventional direct technique that is used in the clinic [4]. The crown was cemented onto the bovine teeth using self-curing temporary cement (Temp-Bond™ Temporary Dental Cement, Kerr Dental, USA).

Table 1: Groups that were tested in the study and the according materials, cement materials and manufacturers information.

|

Group |

Material of temporary crown |

Manufacturer |

Cement material |

|

Group A (Control Group) N=5 |

Bis-acrylic |

Luxatemp Fluorescence DMG, America |

Temp-Bond™ Temporary Dental Cement, Kerr Dental |

|

Group B N=5 |

Hi-tempo window type crown (PLA based resin) with resin cusps |

Hitem, Korea |

Resin cement with nano-filler particles, Hitem |

|

Group C N=5 |

Hi-tempo crown (PLA based resin) |

Hitem, Korea |

Resin cement with nano-filler particles, Hitem |

To prepare the specimens for Group B, a matrix was made using the vacuum press machine of a standard posterior crown of first premolar. The Hi-tempo window crown (Hitem, Korea) was held in 75°c water for ~4 seconds and fitted onto the crown gently, applying light pressure to ensure the best fit around the margin of the preparation. The clear matrix was filled with PLA based resin (Hitem, Korea) and fitted on top of the Hi-tempo window crown and light cured using a light cure machine (Demi™ Plus, Kerr Dental, USA) for 20 seconds. The matrix was removed and the crown was cemented onto the preparation with resin cement (Hitem, Korea) and light cured for 20 seconds. The margin and the areas of the crown that were modified were coated in a clear varnish (Hi-Coat, Hitem, Korea) and light cured until set.

To prepare the specimens for group C, the Hi-tempo crown was held in 75°c water for ~4 seconds and fitted onto the crown gently, applying light pressure to ensure a good fit at the preparation margin. It was cemented onto the preparation with resin cement and light cured for 20 seconds. The margin and the areas of the crown that were modified were coated with a clear varnish and light cured until set. For all the specimens, a waterproof marker pen was used to place a small dot above and below the margin on the buccal, lingual, mesial and distal side, the distance between which was used for measuring any marginal change during cyclic loading. The distance was measured using a stereoscopic zoom light microscope (Nikon, SMZ800, USA) before and after cyclic loading. Measurements were taken from the underside of the inferior dot and topside of the adjacent superior dot. The mean and standard deviations of the gap changes were determined for each side of each group as well as for the mean of all the sides of each group. The mean marginal change values for each group were compared by means of Kolmogorov-Smirnov test. The specimens were placed into a round plastic chamber containing the red pigmented (red food colouring, Hensells, NZ) artificial saliva (Biotene artificial saliva substitute, GSK, UK), ratio 1:20 ml, prior to mounting in the custom made cyclic loading machine.

Table 2: Descriptive statistics of the marginal change observed in three groups (n=5) including the mean, standard deviation (SD), median, P value and 95% confidence interval (CI). Total mean marginal change is calculated Distance before cyclic loading - Distance after cyclic loading.

|

Side |

Group |

Mean |

SD |

95%CI |

P-value |

|

|

|

Min |

Max |

|

|||||

|

(Distance before - after cyclic loading) |

Group A |

813.6 |

1677.83 |

28.34 |

1598.85 |

.000* |

|

|

Group B |

139.74 |

1258.31 |

-530.76 |

810.25 |

|||

|

Group C |

-221.92 |

215.37 |

-322.72 |

-121.12 |

|||

|

Buccal Change |

Group A |

229.4 |

203.1 |

-22.85 |

481.57 |

.016 |

|

|

Group B |

125.95 |

12.64 |

12.23 |

239.67 |

|||

|

Group C |

-142.46 |

95.87 |

-261.5 |

-23.42 |

|||

|

Lingual Change |

Group A |

1028.76 |

2115.77 |

-1598.31 |

3655.83 |

.016 |

|

|

Group B |

-145.5 |

77.19 |

-268.33 |

-22.67 |

|||

|

Group C |

-132.92 |

93.33 |

-248.81 |

-17.03 |

|||

|

Distal Change |

Group A |

844.28 |

1772.27 |

-1356.29 |

3044.85 |

.065 |

|

|

Group B |

-230.5 |

780.17 |

-1199.21 |

738.21 |

|||

|

Group C |

-386.7 |

234.4 |

-677.74 |

-95.66 |

|||

|

Mesial Change |

Group A |

1151.98 |

2254.84 |

-1647.78 |

3951.74 |

.061 |

|

|

Group B |

743.7 |

2148.39 |

-1923.87 |

3411.27 |

|||

|

Group C |

-225.6 |

309.42 |

-609.79 |

158.59 |

|||

* Statistically significant p<0.05

III Cyclic Loading

The specimens were cyclic loaded in the central fossa of the occlusal surface with a 93.36 N force at 0.63 HZ for 45360 cycles. This number of cycles equates to 20 hours and is estimated to stimulate the maximum chewing time by a healthy adult in a period of 21 days, which is equivalent to the average number of days that temporary crowns are placed in a patient’s mouth. To evaluate the structural durability of the tested specimens, the specimens were first assessed visually under light microscope on the axial and occlusal sides of the crown and again after cyclic loading. Areas of change or damage were noted. Two specimens from each group, one with the most visible damage and one with the least visible damage, were selected for analysis using a JEOL JSM-6700F field emission SEM (JEOL Ltd, USA). The samples were prepared by mounting on aluminium pin stubs using double sided carbon tape prior to coating with ~10 nm carbon in an Emitech K575X peltier-cooled high resolution sputter coat (EM Technologies Ltd, Kent, England) fitted with an Emitech 250X6 Carbon coater. The surface roughness and other damage features of the specimens were compared.

IV Nanoindentation Test

Cured samples of each of the materials used in the study were imbedded in epoxy resin (EpoFix, Struers, Norway). The specimens were sequentially polished to a <0.05 colloidal silica finish. Nano-indentation was performed at a static load of 200mN with n=20 indents across the bulk surface. Compliance of the load frame for the nano-indentation unit was 0.2nm/mN. Post data analysis of elastic modulus and hardness were performed using IBIS 2 software.

V Sectioning of Specimens for Visual Analysis

One specimen from each group was randomly selected, dehydrated and cleaned in alcohol, and then infiltrated and embedded in epoxy resin (EpoFix, Struers, Norway). The specimens were then sectioned longitudinally using an MOD 13 diamond cut-off wheel on a Struers Accutom-50 precision cut-off saw (Intellection Pty Ltd, Australia). The specimens were then prepared to a final grit size of 4000 and final section thickness of 1mm prior to viewing in the light microscope.

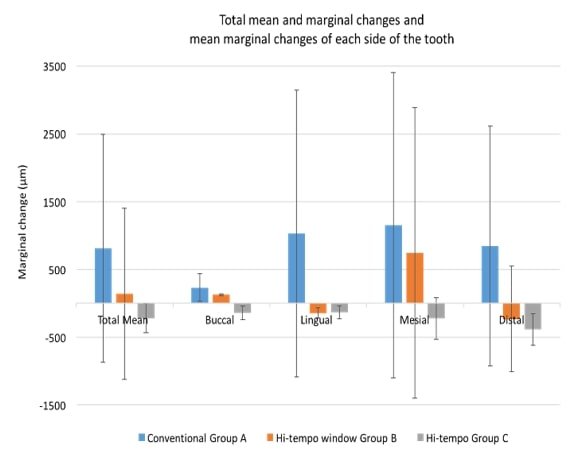

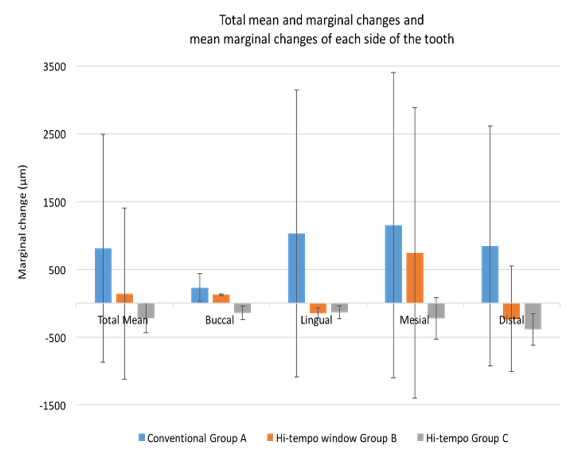

Figure 1: Bar graph representing total mean and marginal changes and mean marginal changes of each side of the tooth.

Results

I Marginal Gap Change

The mean marginal change for group A was 813.60 μm (±1677.83 SD) 95% CI [28.34, 1598.85], for group B was 139.74 μm (±1258.31SD) 95% CI [-530/76, 810.25], and for group C was -221.92 μm (±215.37SD) 95% CI [-322.72, -121.12], (Table 2). These results show that group A had the biggest discrepancy and group B had the smallest discrepancy. The positive values indicate the decrease of the margin gap size and the negative values indicate the increase in gap size of the margin. Statistical analysis revealed that when comparing group, A versus group B the P value was p = 0.013 meaning the change in marginal size was statistically significant. When comparing group, A versus group C the P value was less than 0.001 meaning the change in marginal size was very statistically significant. The mean of each individual side for each group and relative statistical data was calculated and is shown in (Figure 1). For group A the data showed that mesial side had a biggest marginal discrepancy and buccal side had the lowest. For group B mesial side had the biggest marginal discrepancy and buccal side had the lowest. For group C distal side had the biggest marginal discrepancy and lingual side had the lowest.

II Structural Durability

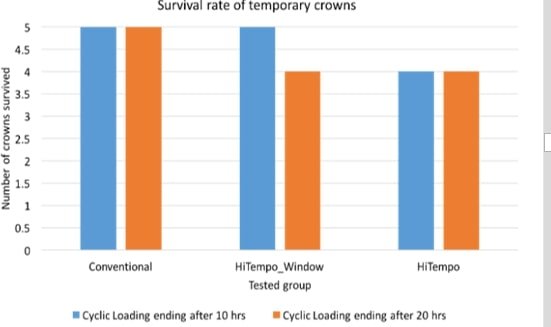

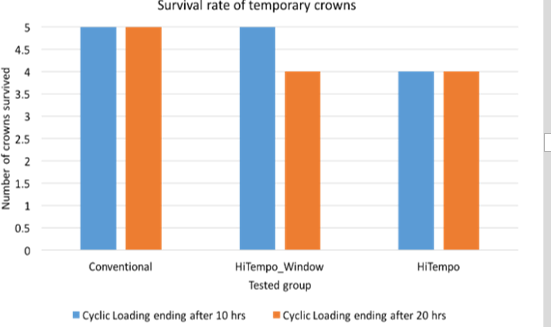

After cyclic loading the specimens in group A, all specimens survived after cyclic loading for 20 hours, in group B, 1 specimen failed after 10 hours of cyclic loading, in group C, 1 specimen failed after 2 hours of cyclic loading as shown in (Figure 2), giving a 80% survival rate in group B and C and 100% surval rate in group A.

Figure 2: Bar graph representing survival rate of each group tested.

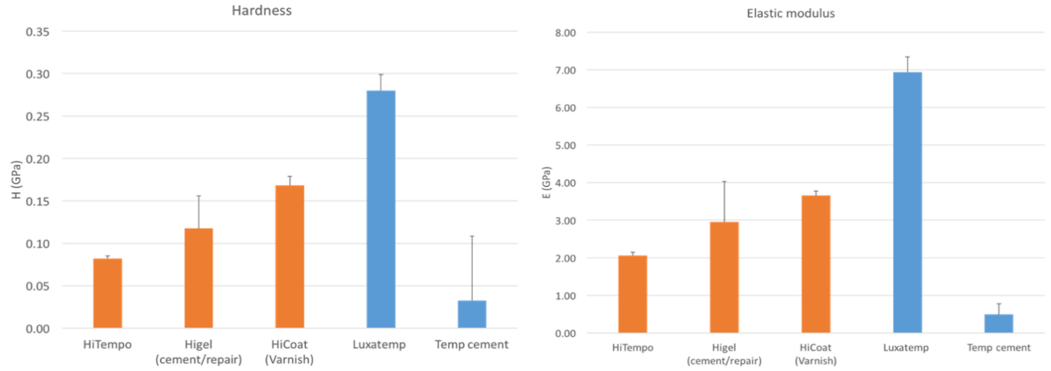

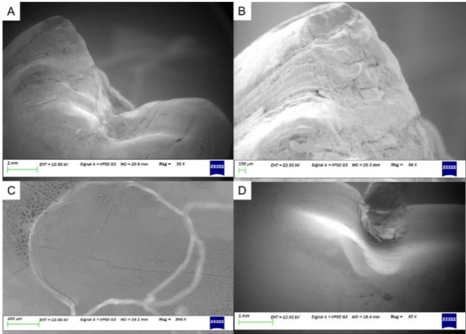

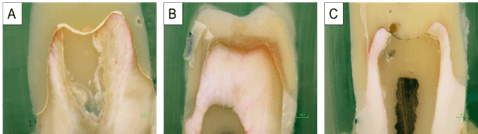

The nanoindentation test of the materials used for each group showed crown Luxatemp (bis-acrylic) conventional temporary crown material (used for group A) having the highest value for hardness and elastic modulus and Hi-tempo temporary crown material (used for group C) having the lowest value for hardness and elastic modulus (Figure 3). SEM analysis showed that the conventional temporary crowns had a rough surface with micro cracks. In contrast, the Hi-tempo group showed a smooth and homogeneous surface due to its prefabricated nature. This was similar to the Hi-tempo window group, but some surface cracks and porosity was observed at the junction of the resin and the pre-made temporary crown which is shown in (Figure 4). When analysing the sectioned specimens visually, it was noted that the red dye had penetrated (microleakage) though the margin into the fitting surface in all the specimens (Figure 5).

Figure 3: Bar graph demonstrating hardness and elastic modulus results from the nano-indentation test.

Figure 4: A) Occlusal surface of a conventional crown. Minimal damage from the loading pin is seen; B) Rough and cracked surface of conventional crown; C) Crack propagation in Hi-tempo window crown and porosity of resin; D) The occlusal indentation from the cyclic loading pin in Hi-tempo crown. Smooth and homogenous surface is observed.

Figure 5: A) Cross section of the specimen representing group A; B) Cross section of the specimen representing group B; C) Cross section of the specimen representing group C.

Discussion

Having an adequate marginal seal and good structural durability are some of the key factors that contribute to a successful temporary restoration such as a crown [3]. In the literature, various studies have been performed to test the conventional temporary crown’s marginal integrity and structural durability, which includes testing it under cyclic loading in stimulated oral environment [13]. However, in the current literature, there are no studies that have tested the novel Hi-tempo temporary crown system. The novelty of this system is that the restorations come in pre-shaped form and made from PLA based resin thermoplastic material. Use of such a system could potentially save resources such as chair time and costs of treatment. Hence, the objective of this study was to evaluate the efficacy of a novel temporary crown system (Hi-tempo) marginal seal and structural durability in terms of cyclic loading.

The methodology described in this report includes a novel system of manufacturing a crown preparation. In the literature, many studies that conducted marginal integrity tests used artificial dies such as Ivolen material or metal (stainless steel) dies [3, 14]. Even though these are widely used methods, it raises the concern that these materials are biologically different to human teeth which could compromise the bond between the crown preparation and the temporary crown. The use of bovine teeth to simulate human teeth for mechanical testing has been observed in the literature for many years [15]. Even though extracted human teeth have been used in some studies and they are usually preferred, they are difficult to obtain and require an ethical approval process that could be time-consuming [16]. The use of bovine teeth is well established for dental material bond strength testing but there is a little literature regarding using bovine teeth to manufacture a crown preparation used for crown marginal integrity testing [17]. In this study, a novel method of copy milling the bovine teeth for the crown preparations was used. The bovine teeth were manually milled using a 3D printed die by means of a copy mill machine. Because the samples were copy milled using an existing 3D printed preparation, the 15 bovine teeth preparations had accurate dimensions and parameters similar to a crown preparation that could be seen in the clinic. Therefore, due to the specimens being identical the results that were produced from this study would be more clinically relevant. Furthermore, in past studies where human teeth were used to test marginal integrity, the teeth were cut to shape manually which introduced an inconsistency to the study and the results [18].

When the specimens were tested for marginal integrity the difference between the average marginal changes were statistically significant (p<0.05) between the conventional (Group A) versus the Hi-tempo window (Group B), and Hi-tempo (Group C). However, some ranking change between the individual sides was present. The conventional temporary crown specimens in group A showed the biggest marginal discrepancy (813.60 μm). The values of the marginal change mean of individual specimens and the total marginal change mean of group A were all positive. When looking at the total marginal change group B had the lowest marginal discrepancy (139.74 μm). However, when considering the mean marginal changes for individual sides they consisted of negative and positive values. The positive values indicated a decrease in the gap size and the negative indicated an increase.

One aspect to note when considering marginal change of all the groups is the cement that was used for each sample. According to Rosenstiel and Gegauff (1988) the temporary luting material should have low strength and an obtundent effect on freshly prepared dentin. This is important because all traces of temporary cement must be removed to maximise adhesion when the permanent restoration is placed [19]. For group A the temporary cement that was used was zinc-oxide eugenol-based (ZOE). This cement has relatively low strength compared to other cements used in the market, which might have resulted in larger marginal change [20]. During the cementation the luting resin can result in polymerization shrinkage therefore decreasing the marginal gap [21]. In previous literature, it is noted that adhesion may be distributed by the development of shrinkage stress [22]. Furthermore, temporary cement is critical for a successful temporary restoration as it aids in providing a seal between the temporary crown and the tooth preparation. However, when visually analysing the cross section of specimens from each group some staining from the dye was noticed in all specimens which means that during cyclic loading of the specimens some liquid has penetrated through the marginal seal. This also could mean that in the clinical setting, due to microleakage, bacteria could also penetrate the marginal seal.

When considering the luting agent used with group B and C which was a resin-based cement with nano-filler particles, this resin is used as a cement and to build up crown cusps therefore the properties of it differ from the ZOE cement. This different is shown in the nanoindentation test results (Figure 3). The hardness and elastic modulus of temporary cement used in group A was 0.03H (GPa) and 0.49E (GPa) respectively and the resin cement used for groups B and C was 0.12H (GPa) and 2.95E (GPa) respectively. This may be the reason that group B and C had lower marginal discrepancies as the Hi-gel cement was around four times harder which could affect the margin integrity. However, the fact that the hardness and elastic modulus is much greater than of ZOE cement, could possibly raise the question whether it would be harder to remove all the residual cement from the preparation prior to bonding the permanent crown. Therefore, further studies should be conducted to test this.

When considering the mean dimensional changes of the individual sides of all the specimens some ranking change was noticed. The distal and mesial sides had biggest discrepancies in the three groups, whereas buccal and lingual sides had the smallest discrepancies (Figure 1). Therefore, this displays a pattern of the marginal changes according to which side it was. A possible reason for this could be the crown preparation design. Due to the nature of the tooth, the mesial and distal sides had shorter axial walls to the margin than buccal and lingual sides. Because this type of preparation is observed in most clinical situations, these results might be more clinically relevant compared to studies where a die with the same length of axial wall provides a uniform all-round circumference [14].

The indentation tests and the SEM images that were taken provided a better understanding of the structural durability of the materials that were used in this study. The conventional temporary crown material used for group A showed larger hardness and elastic modulus. The materials used in group B and C showed a significantly lower hardness and elastic modulus (Figure 3). The SEM images that were taken of group C (Figure 4) showed an indentation from the loading pin on the occlusal aspect of the crown. This indentation was also visible upon initial inspection of the crown. The SEM images of group A did not reveal any indentations to the same extent where the pin contacted the occlusal aspect. These observations coincide with the indentation test results as the material with lower hardness showed greater indentation in the occlusal area. However, it should be noted that in the mouth the temporary crowns would not be loaded on one area constantly like the pin was, but the forces would be more spread out across the occlusal table of the crown.

When visually examining the surface texture of axial walls of the specimens, group B and C had much smoother surfaces than group A (Figure 4). In addition, the cusps of group A appeared to have a number of micro cracks of various depths and length along the surface. Formation of these micro cracks appears to be due to the stresses that were introduced due to cyclic loading. The presence of the micro cracks are potential sites of crack initiation which could propagate to failure thereby shortening the life of the crowns were they cyclic loaded for a longer period than carried out in the study. In contrast, the crown surface areas of group B appeared more homogenous (Figure 4). This is due to the crown being made from a PLA resin-based material and the preformed nature of axial walls. However, even though the cusps were built up in resin, the intersection of the two materials was not easily identified thereby providing a homogenous surface for the temporary crown. The crown surfaces of group C were homogenous in appearance due to being preformed from the PLA material. No micro cracks were observed. The smoother surfaces in the area of the margins of the crowns in group B and C has positive implications for reduced biofilm adhesion when patients carry out routine oral hygiene, especially interproximally.

There were some limitations to the study. Despite statistical analysis showing statistical significance between the conventional temporary crown group and Hi-tempo groups the sample size of five for each group was too small to make definite conclusions. The data for each group was also widely distributed which is also a limitation. Therefore, in future, studies on a bigger sample size (of at least 10 specimens per group similar to previous studies in this area of research cited in the literature) is recommended [13, 23].

Conclusion

Within the limitations of this pilot study, the marginal change of the conventional temporary crowns versus the thermoplastic crowns was significantly greater (p<0.05). The surface texture and structure of the conventional crown system appeared to be rougher and filled with micro cracks in contrast to the two PLA systems which showed smoother more homogeneous surfaces. The two PLA systems showed greater indentations from the occlusal contact cyclic loading pin than the conventional acrylic crown system.

Acknowledgments

The Authors acknowledge the following people who supported the study: Ludwig Jansen van Vuuren, Liz Girvan from the Otago Centre for Electron Microscopy, Kc Li, Ajay Sharma from the University of Otago. The authors also thank Hitem (Korea) for supplying materials for the study.

Article Info

Article Type

Research ArticlePublication history

Received: Mon 02, Dec 2019Accepted: Wed 08, Jan 2020

Published: Tue 28, Jan 2020

Copyright

© 2023 Joanne Choi. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Hosting by Science Repository.DOI: 10.31487/j.DOBCR.2020.01.01

Author Info

Caitlin Richardson Joanne Choi John Neil Waddell Linda Duoduo Zhou Liza Yelyzaveta Tykhonova Maykon Dias

Corresponding Author

Joanne ChoiSir John Walsh Research Institute, Faculty of Dentistry, University of Otago, Dunedin, New Zealand

Figures & Tables

Table 1: Groups that were tested in the study and the according materials, cement materials and manufacturers information.

|

Group |

Material of temporary crown |

Manufacturer |

Cement material |

|

Group A (Control Group) N=5 |

Bis-acrylic |

Luxatemp Fluorescence DMG, America |

Temp-Bond™ Temporary Dental Cement, Kerr Dental |

|

Group B N=5 |

Hi-tempo window type crown (PLA based resin) with resin cusps |

Hitem, Korea |

Resin cement with nano-filler particles, Hitem |

|

Group C N=5 |

Hi-tempo crown (PLA based resin) |

Hitem, Korea |

Resin cement with nano-filler particles, Hitem |

Table 2: Descriptive statistics of the marginal change observed in three groups (n=5) including the mean, standard deviation (SD), median, P value and 95% confidence interval (CI). Total mean marginal change is calculated Distance before cyclic loading - Distance after cyclic loading.

|

Side |

Group |

Mean |

SD |

95%CI |

P-value |

|

|

|

Min |

Max |

|

|||||

|

(Distance before - after cyclic loading) |

Group A |

813.6 |

1677.83 |

28.34 |

1598.85 |

.000* |

|

|

Group B |

139.74 |

1258.31 |

-530.76 |

810.25 |

|||

|

Group C |

-221.92 |

215.37 |

-322.72 |

-121.12 |

|||

|

Buccal Change |

Group A |

229.4 |

203.1 |

-22.85 |

481.57 |

.016 |

|

|

Group B |

125.95 |

12.64 |

12.23 |

239.67 |

|||

|

Group C |

-142.46 |

95.87 |

-261.5 |

-23.42 |

|||

|

Lingual Change |

Group A |

1028.76 |

2115.77 |

-1598.31 |

3655.83 |

.016 |

|

|

Group B |

-145.5 |

77.19 |

-268.33 |

-22.67 |

|||

|

Group C |

-132.92 |

93.33 |

-248.81 |

-17.03 |

|||

|

Distal Change |

Group A |

844.28 |

1772.27 |

-1356.29 |

3044.85 |

.065 |

|

|

Group B |

-230.5 |

780.17 |

-1199.21 |

738.21 |

|||

|

Group C |

-386.7 |

234.4 |

-677.74 |

-95.66 |

|||

|

Mesial Change |

Group A |

1151.98 |

2254.84 |

-1647.78 |

3951.74 |

.061 |

|

|

Group B |

743.7 |

2148.39 |

-1923.87 |

3411.27 |

|||

|

Group C |

-225.6 |

309.42 |

-609.79 |

158.59 |

|||

* Statistically significant p<0.05

References

- Abohamar S, Federlin M, Hiller K, Friedl K, SchmalzG (2005) Effect of temporary cements on the bond strength of ceramic luted to dentin. Dent Mater 21: 794-803. [Crossref]

- Abouelatta OB, El-Bediwi A, Sakrana A, Jiang XQ, Blunt L (2006) Surface integrity of provisional resin materials. Meas Sci Technol 17: 584-591.

- Balkenhol M, Knapp M, Ferger P, Heun U, Wostmann B (2008) Correlation between polymerization shrinkage and marginal fit of temporary crowns. Dent Mater 24: 1575-1584. [Crossref]

- Boberick K, Bachstein T (1999) Use of a flexible cast for the indirect fabrication of provisional restorations. J Prosthet Dent 82: 90-93.

- Burns D, Beck D, Nelson S (2003) A review of selected dental literature on contemporary provisional fixed prosthodontic treatment: Report of the Committee on Research in Fixed Prosthodontics of the Academy of Fixed Prosthodontics. J Prosthet Dent 90: 474-497. [Crossref]

- Camargo C, Siviero M, Camargo S, de Oliveira S, Carvalho C, Valera M (2007) Topographical, Diametral, and Quantitative Analysis of Dentin Tubules in the Root Canals of Human and Bovine Teeth. J Endod 33: 422-426. [Crossref]

- Campagni W, Majchrowicz M (1991) An accelerated technique for casting post and core restorations. J Prosthet Dent 66: 155-156. [Crossref]

- Castelnuovo J, Tjan A (1997) Temperature rise in pulpal chamber during fabrication of provisional resinous crowns. J Prosthet Dent 78: 441-446. [Crossref]

- Dumbrigue H (2003) Composite indirect-direct method for fabricating multiple-unit provisional restorations. J Prosthet Dent 89: 86-88. [Crossref]

- Ehrenberg D, Weiner GI, Weiner S (2006) Long-term effects of storage and thermal cycling on the marginal adaptation of provisional resin crowns: A pilot study. J Prosthet Dent 95: 230-236. [Crossref]

- Miller S (1983) The anterior fixed provisional restoration: A direct method. J Prosthet Dent 50: 516-519. [Crossref]

- Nejatidanesh F, Lotfi HR, Savabi O (2006) Marginal accuracy of interim restorations fabricated from four interim auto polymerizing resins.J Prosthet Dent 95: 364-367. [Crossref]

- Nejatidanesh F, Momeni G, Savabi O (2009) Flexural Strength of Interim Resin Materials for Fixed Prosthodontics. J Prosthodont 18: 507-511. [Crossref]

- Regish K, Sharma D, Prithviraj D (2011) Techniques of Fabrication of Provisional Restoration: An Overview. Int J Dent 2011: 134659. [Crossref]

- Robinson F, Hovijitra S (1982) Marginal fit of direct temporary crowns. J Prosthet Dent 47: 390-392.

- Rosenstiel S, Gegauff A (1988) Effect of provisional cementing agents on provisional resins. J Prosthet Dent 59: 29-33. [Crossref]

- Rosenstiel S, Land M, Crispin B (1998) Dental luting agents: A review of the current literature. J Prosthet Dent 80: 280-301. [Crossref]

- Schilke R, Baub O, Lisson JA, Schuckar M, Geurtsen W (1999) Bovine dentin as a substitute for human dentin in shear bond strength measurements. Am J Dent 12: 92-96.

- Teruel J, Alcolea A, Hernández A, Ruiz A (2015) Comparison of chemical composition of enamel and dentine in human, bovine, porcine and ovine teeth. Arch Oral Biol 60: 768-775. [Crossref]

- Verzijden C, Feilzeri A, Creugers N, Davidson C (1992) The Influence of Polymerization Shrinkage of Resin Cements on Bonding to Metal. J Dent Res 71: 410-413. [Crossref]

- Tjan A, Grant B (1987) Marginal accuracy of temporary composite crowns. J Prosthet Dent 58: 417-421. [Crossref]

- Yu L, Dean K, Li L (2006) Polymer blends and composites from renewable resources. Prog Polym Sci 31: 576-602.

- Mulimani P (2017) Green dentistry: the art and science of sustainable practice. Br Dent J 222: 954-961. [Crossref]